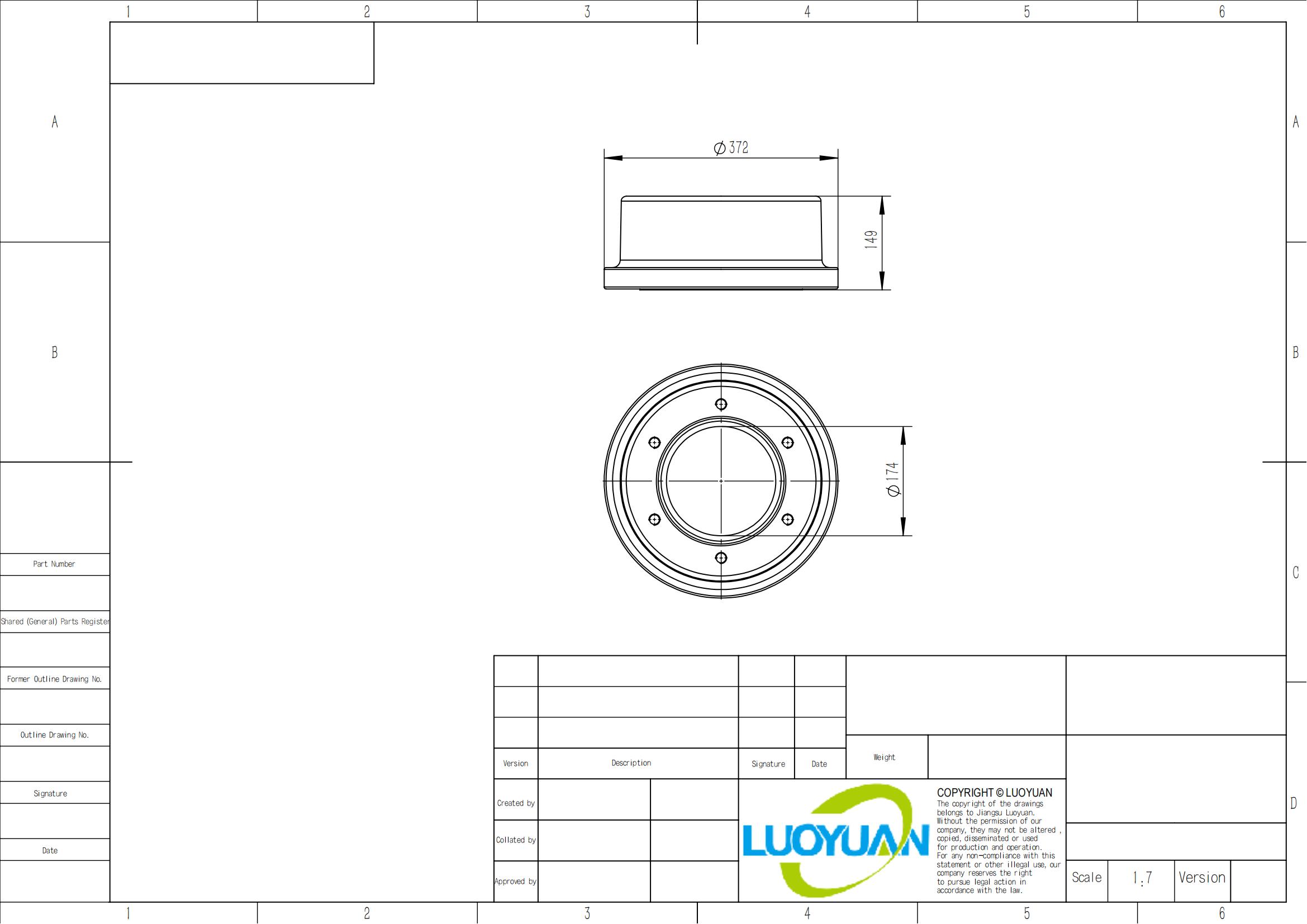

The running wheel assy material is 42CrMo. During the casting process, the product undergoes surface medium frequency quenching heat treatment, as well as magnetic particle inspection and ultrasonic testing. The appearance dimensions of the product are also 100% size inspected.

Yield Strength :

≥ 355Tensile Strength :

≥ 600Percent Elongation % :

≥ 12Hardness :

≥ 50

Our hours

Mon- Fri : 9 AM - 5 PM

(all hours are Eastern Time)