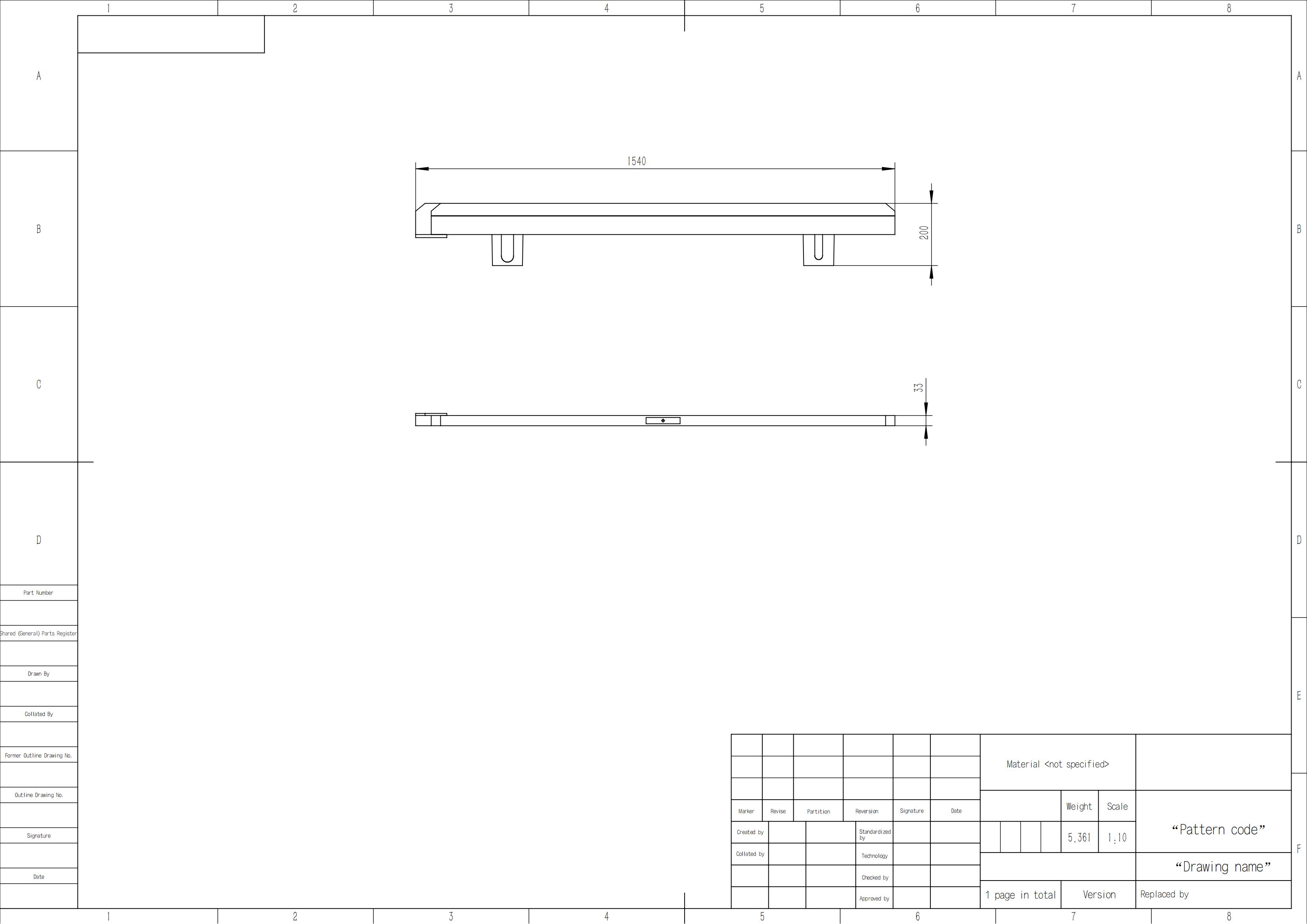

The rod drop seal material is Q235+65Mn. During the casting process, the product undergoes surface paint rust prevention treatment,. The appearance dimensions of the product are also 100% size inspected.

Yield Strength :

≥ 235Tensile Strength :

≥ 370Percent Elongation % :

≥ 26Surface Hardness HRC :

≥ 45

Our hours

Mon- Fri : 9 AM - 5 PM

(all hours are Eastern Time)